Emma Chaplin

Day Two of our Apple Course with Plumpton - pressing the juice

Both groups came along on consecutive days to the Stanmer Park Fruit Factory in early October. The Fruit Factory is part of Brighton Permaculture Trust (BPT). Stephan Gehrels ran the days for us. The interns brought along the apples they'd picked from Ringmer Community Orchard on Flourish's apple course day one to be pressed, bottled and pasteurised.

Here is a video we made about this process

We had unpredictable weather both days, with some rain, but the interns were well-equipped in terms of raincoats, and the Fruit Factory has a nice indoor area we could use as well. It smelled deliciously of ginger because Stephan was cooking a big pot of it to be blended with some of BPT's juice made from apples from their local orchards.

Stephan welcomed everyone, told us about Brighton Permaculture Trust and talked about the work he does as BPT's Eco Schools Project Manager. He said the favourite part of his job is "working with young people and helping them understand how to protect the planet". The thing he likes least is: "paperwork and heavy rain".

He talked about making apple juice and apple vinegar - and how healthy it is. He covered health and safety issues, such as asking if everyone was feeling well that day, explaining people with long hair had to tie it back (essential in all food prep) and the importance of hand-washing. He told us where the toilets were and suggested we be careful not to trip over things, such as the hose or buckets.

Stephan showed us how to use the water lock on the hose, how to wash the apples and cut them up safely with a sharp knife. We were to discard any rotten bits and put them in particular buckets, which he said go to local pigs as food. Interns split into different groups to do different tasks, and switched around, so everyone got the chance to try activities they were interested in. The chopped apple pieces went into the big yellow mill or macerator, to chop them into bits, ready for juicing. The buckets of this chopped apple were then tipped into the hydro-press until it was full.

Then (for me!) the most exciting part, we got the hydro-press going to squueze all the fresh juice out of the apple pulp. We screwed the metal lid on tightly, then turned the hose (attached to the press) on. The hydro-press uses water pressure via a big rubber balloon in the middle of the pulp to squeeze all the juice out. Gallons of it poured out of the bottom lip into the buckets we put underneath. We had to keep an eye on them and change bucket every time one was nearly full.

Some of the raw juice was bottled and sealed by the students into plastic cartons to take home. It has to be drunk within a couple of days.

The groups also drank some juice 'raw' - each day we used various types of apple we'd picked (Red Falstaff on Day One, Ashmead's Kernel on Day Two) in different combinations to see if they tasted different. The day two mix including bramley apples, which gave a lovely tartness. the group also tried cider, after Stephan checked that everyone was 18 or over. The comments were:

LUSH

zingy

super, fresh

sweet

I will never shop at Tesco again

highly addictive

light

feels like it's doing you good

Then Stephan explained about how 'cooking' the juice in sterilised bottles will preserve it for up to a year, although it does change the taste. The groups poured juice from jugs into bottles, which then went (carefully) into the pasteurisers to be heated in hot water to the right temperature. So that's what we did with the rest of the juice.

Everyone worked hard and enjoyed themselves.

Then we broke for lunch, and in the afternoon, Peter May came along to show the groups around the Stanmer orchards.

Next stage: bottle label design and marketing - plus visits to a pub and a cider maker!

Emma Chaplin

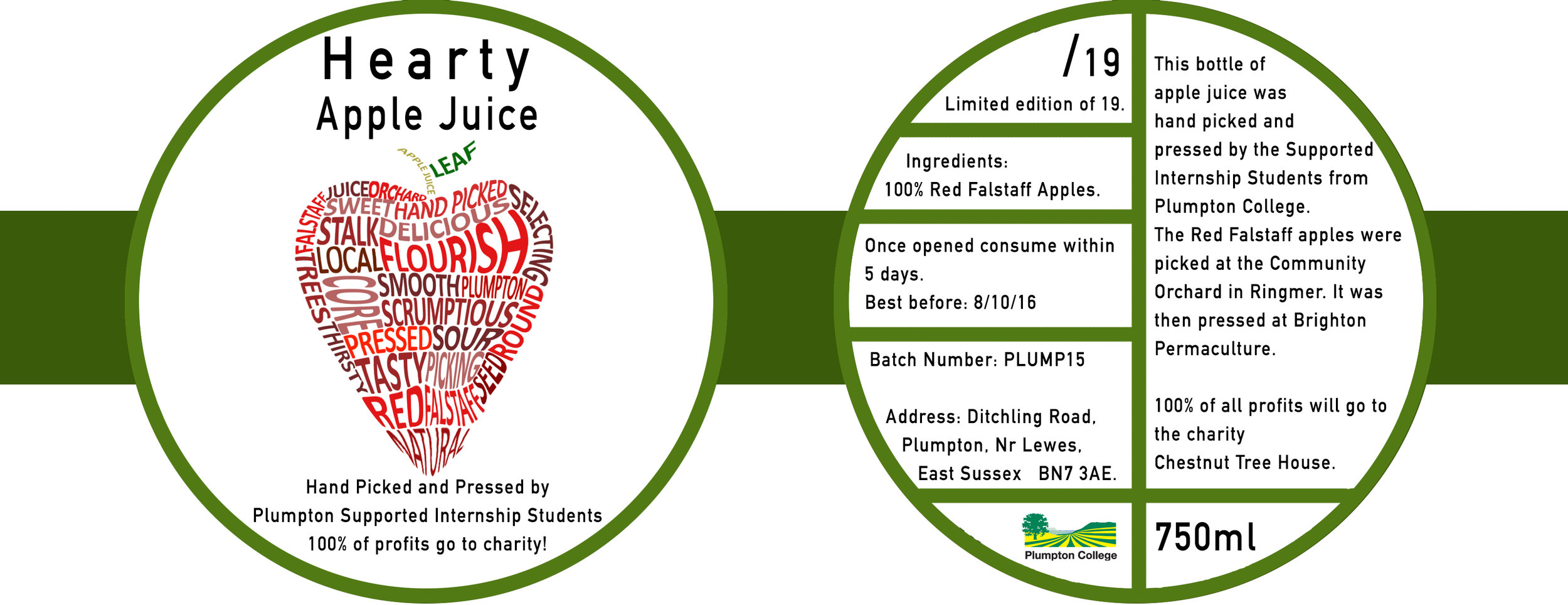

Apple juice label - final design from Plumpton

This is the final Ringmer Community Orchard apple juice label, designed by the Plumpton College supported interns with the assistance of the wine department. Read all about how it was produced here. We think it's great. Well done all.

This is the final Ringmer Community Orchard apple juice label, designed by the Plumpton College supported interns with the assistance of the wine department. Read all about how it was produced here. We think it's great. Well done all.

EC

Our three day course with Plumpton College Supported Interns

Ringmer Community Orchard, under the guidance of Common Cause director Katharine Finnegan, has become a thriving orchard over the years, with many varieties of apple trees and other fruits. Flourish came into being in September 2015, and one of the first tasks of project manager Emma Chaplin was to create and carry out a three-day course based around these apples for the class of fifteen Plumpton College supported interns.

This Emma did in consultation with apple expert Peter May, Plumpton supported interns course leader Mel Simmonds, and others.

Day one

This took place at the end of September at Ringmer Community Orchard. The day was run by Peter May, supported by Emma and several Plumpton support staff, including Mel and Nikki Sanger. During the day, Peter talked to the group about how apples grow, how many different varieties there are, plus offering advice on safe handling of heavy items. From Peter, the interns learnt how to pick, grade and weigh the Red Falstaff apples. There were also discussions about what working in the fruit picking industry might entail and what qualities you might want for such roles.

Day two

This took place at the beginning of October at Brighton Permaculture in Stanmer Park. Peter May and Emma Chaplin brought along the apples the students had picked at Ringmer Orchard. Stephan Gehrels of Brighton Permaculture led the day, demonstrating and supporting the interns in how to wash, macerate and press the apples using the hydropress. He also answered any questions the students had about the process.

Everyone tasted the freshly pressed juice - and said they thought it was delicious. The interns poured half of it into cartons. A passer-by bought a carton of it from intern Gemma.

Stephan talked about bottling apple juice, adding flavours, what labels are added. He also showed the interns the cider press. Then the interns bottled the rest of the juice into 19 bottles, which they then pasteurised, to make the juice longer-lasting. The interns took these home with them.

The day ended with a Stanmer orchard tour by Peter May.

This was some of the feedback we got after days one and two: "Grading of apples, picking and storing was really interesting." "The orchard tour was really good". "The fresh apple juice was much better than shop bought". "Learning the different names of the apples was interesting". "I liked learning how to make juice and tasting it". "The people were passionate about their project, this was contagious".

Next...

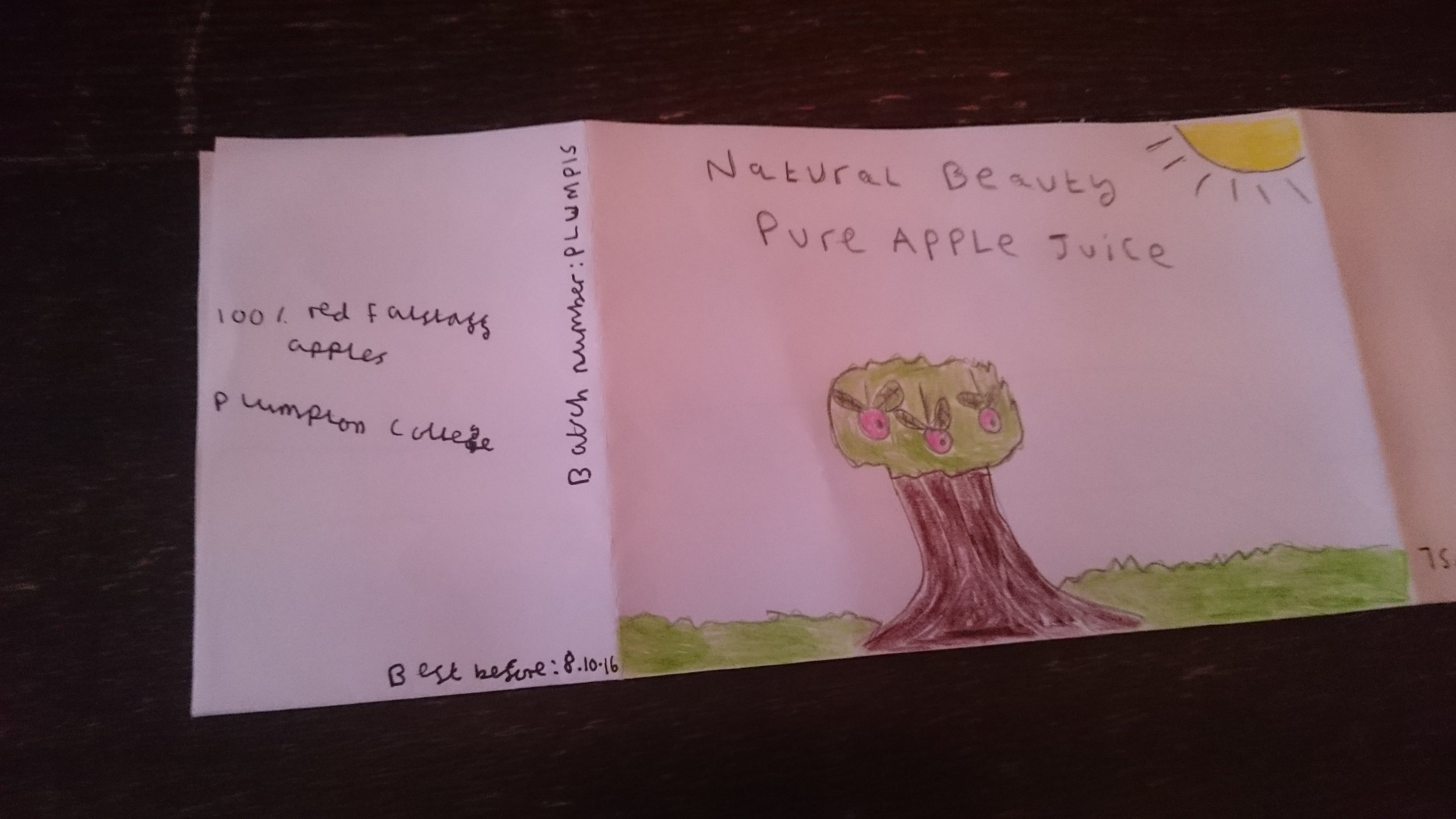

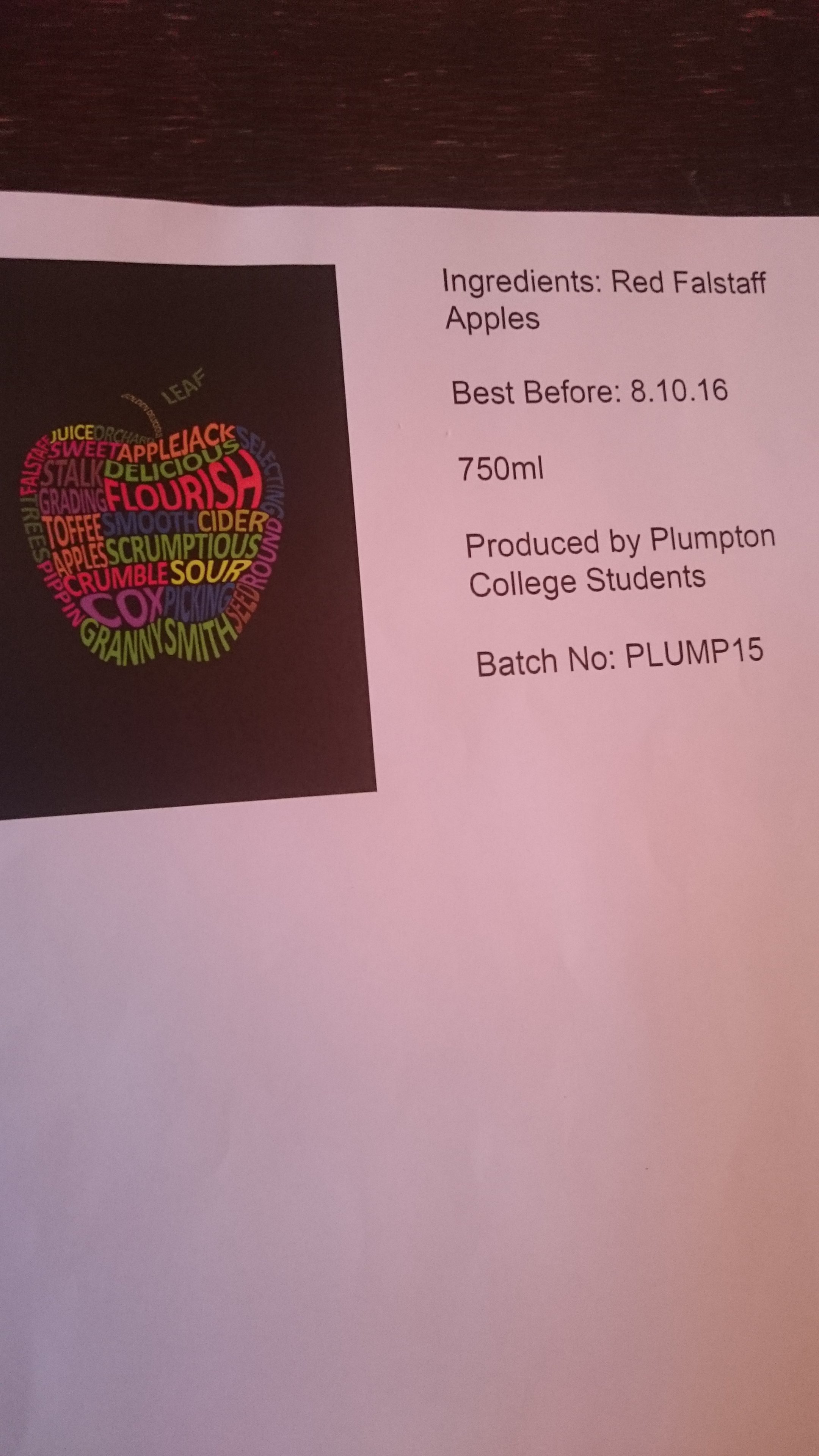

The interns went back to college to design labels for their bottles with their resident expert graphic design tutor. They had advice and examples from Stephan and Emma about what the bottle labels needed to include, and graphic designer Neil Gower (who has designed beer bottles, amongst many other things) contributed advice on good label design.

Day three

This was split into two. The interns came by bus to Lewes at the beginning of December with Nikki Sanger and Mark Gilbert as support staff plus others, where Emma met them off the bus.

They visited the Elephant and Castle pub, went upstairs to the function room where landlord Huw Jones spoke to them about running a pub, how he came to be a pub landlord, what jobs there are in pubs and what qualities you need to do them.

The students had prepared a large number of questions for Huw, which he was able to answer very helpfully. Sara Grisewood from Pleasant Stores came and joined the group and told them about her local vegetarian cafe/shop business. Then Huw and Sara tasted the apple juice, gave incredibly positive feedback about the taste and how good a product it is. They said there were so many factors that would work for them as buyers – the fact that it's made by Plumpton interns, is limited edition, from a single variety of apples grown locally, that no chemicals used in the process or used on the apple trees. They said they would definitely stock it if they could.

Sara Grisewood from Pleasant Stores came and joined the group and told them about her local vegetarian cafe/shop business. Then Huw and Sara tasted the apple juice, gave incredibly positive feedback about the taste and how good a product it is. They said there were so many factors that would work for them as buyers – the fact that it's made by Plumpton interns, is limited edition, from a single variety of apples grown locally, that no chemicals used in the process or used on the apple trees. They said they would definitely stock it if they could.

They also explained how much they’d pay for a bottle, and how much they’d charge if they were selling it on.

They gave feedback on all the label designs the students had come up with.

Sara talked about products she stocks and, on the way back to the bus stop, the interns dropped into Pleasant Stores, where she showed them some labels of her drinks.

Final half day

The next day, Emma went to Plumpton College and talked to the students about Twitter – what it is, how to use it effectively, how to be safe on Twitter. She answered questions about tweeting, then gave a handout on this. She also presented the interns with certificates of attendance for the whole three days of the apple-based course.

The final outcome of this project will be that the interns will work with the wine department at Plumpton to produce the labels, based on the best bits of an amalgam of designs. Watch this space for that.

The juice will be sold at the Plumpton College Christmas Fair, with all money raised going to Chestnut Tree Hospice.